Boot Wash Area Installation for Leading Midland Savoury Food Producer

- Client: Leading Midland Savoury Food Producer

- Project: Boot Wash Area Installation

- Project Value: £7,500

- Products Used: KDR Polyfloor, Polycove, Polyjoint & Ardex A38 Screed

- Area: Approximately 7 Linear Metres Commencement

- Date: September 2024

- Works Duration: 4 Weekend Visits

Project Description

To maintain the highest hygiene standards, a leading Midland savoury food producer required the installation of a new stainless steel boot wash facility between production areas and changing rooms. This essential upgrade aimed to enhance cleanliness and safety within the food production facility.

Challenge

The key challenge in this project was the reduction of the existing concrete floor level by 70mm, while ensuring the new surface would be perfectly flat and level for the installation of the stainless steel boot wash tray. Given the high hygiene standards of the food production facility, the solution also needed to be robust, easy to clean, and fully compliant with food safety regulations.

Solution

Zenith’s Flooring Division took a multi-phase approach over four weekend visits to minimise disruption to the client’s operations:

Phase 1: The existing concrete floor was mechanically broken out to reduce the floor level by 70mm. This created a flat and level surface and formed a 50mm-deep rebate for the new stainless-steel wash tray. Ardex A38 polymer screed was used at a nominal thickness of 20mm to reinstate the floor, ensuring durability and stability for the installation.

Phase 2: A new stainless-steel inlet was supplied and installed, connecting to the existing drainage system to ensure water flow and hygiene.

Phase 3: After the installation of the new stainless-steel trays by a third party, Zenith applied a cove skirting using KDR Polycove PU cove grade, which provided a seamless transition between the floor and walls for improved cleanliness.

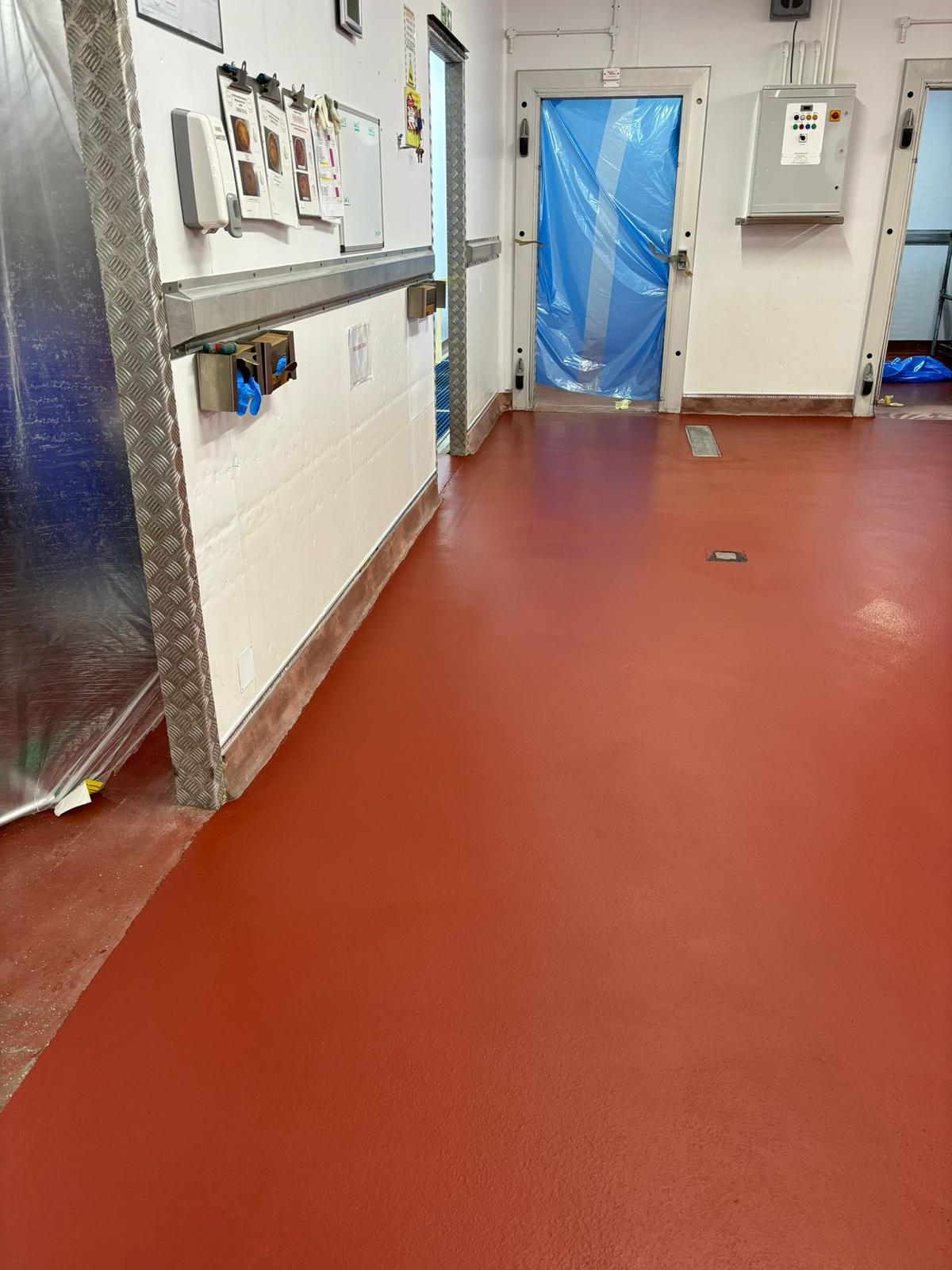

Phase 4: The remaining floor area adjacent to the wash trays was finished with KDR Polyfloor PU screed at a thickness of 9mm. This was applied flush with the stainless-steel trays to create a smooth, seamless surface. KDR Polyjoint expansion joints were then installed, completing the project. All KDR products were applied in the colour Carmine for a vibrant, professional finish.

Outcome

The boot wash area installation was completed to the highest standards, providing a durable, hygienic, and aesthetically pleasing solution. The new floor surface is easy to clean, highly resistant to wear and tear, and fully compliant with hygiene requirements in the food production industry. The client was extremely satisfied with the quality of the work and the minimal disruption to their operations, thanks to the efficient scheduling over four weekend visits.

Zenith Contract Services delivered a comprehensive solution, ensuring that the new boot wash facility met all the necessary safety and hygiene standards while also providing a professional, polished look.

For more information, please call us on 024 7668 7167 or email info@zenithcontractservices.co.uk

To download a PDF version of this case study, please click here